Suzhou Xunshi New Material Co., Ltd (refered as

Xunshi afterwards) is a professional supplier of high performance alloys. Our factory

is specialized in manufacturing Nickel alloys & Cobalt alloys for

10+ years,with a company mission to provide a high quality, reliable

source for precision alloys, high temperature alloys and stainless

steels in both pilot run and mass production. We are professionally

manufacturing materials with unique features, which are then used

in aerospace, military, electronics, marine, petroleum and

petrochemical industries.

Base on “Quality-oriented, Leading Technology, Continuous

Improvement, Customer Satisfaction”, we believe Xunshi could be

your best supplier.

Product Scope of Xunshi

· Inconel

· Hastelloy

· Incoloy

· Monel

· Nimonic

· Nitronic

· Haynes

· Special Stainless Steel

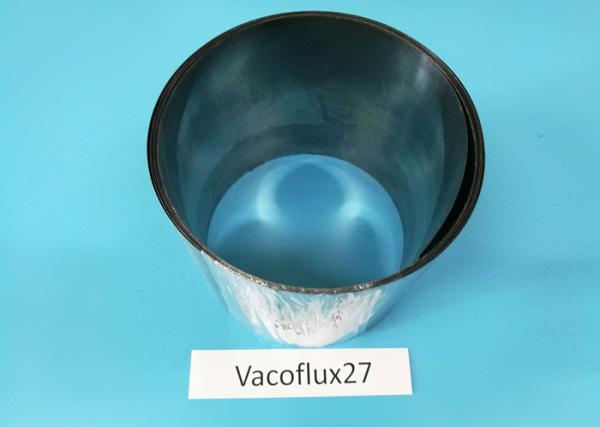

· Soft Magnetic Alloy

· Permanent Magnetic Alloy

· Elastic Alloy

· Controlled Expansion Alloy

· Magnetostrictive Material

Services of Xunshi

· Material selection

· Non-standard product research and pre-production

· Hard to find material sourcing

· Cutting/splitting

· Precision machining

· Heat treatment

· Customized Packing

· Logistics service

Advantages of Xunshi

· Experienced in industry

· Quality control system

· Authorized Certificates

· Guaranteed delivery and quality

· Customers from 30+ countries trust us

Xunshi is engaged in introducing China-origin high performance alloys to

the entire world. Choose Xunshi, choose high performance.